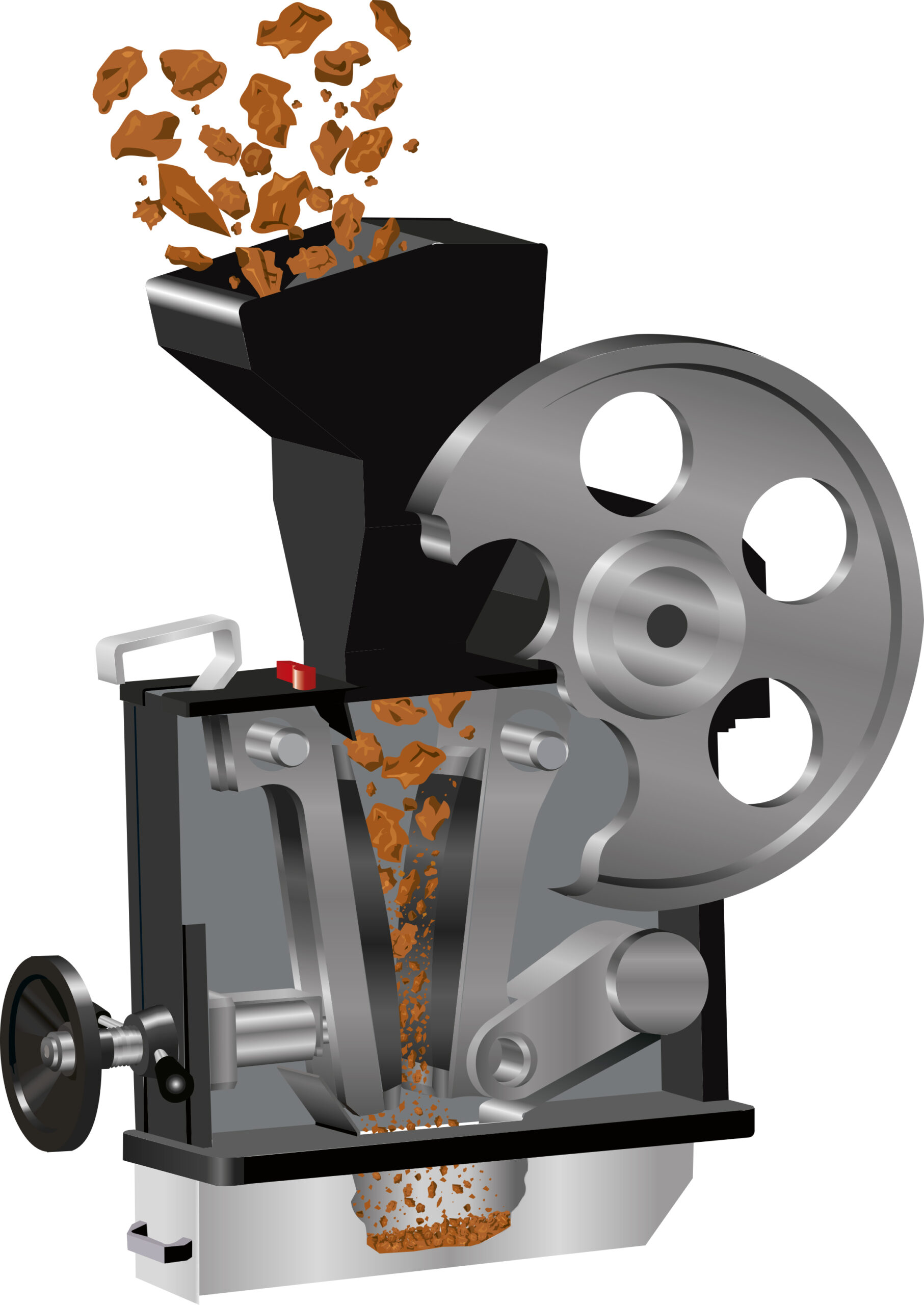

Jaw Crusher Machine for Heavy-Duty Crushing

The Equilab Jaw Crushers are grinding units especially designed for the primary

reduction of semi-hard, hard, brittle and tough materials. Able to quickly and efficiently crush glass, earth, slag, metallic oxides, cements and construction materials, ferroalloys, ceramic materials, minerals and stones.

These are very robust and simple units, that can take in and reduce samples for years practically maintenance free.

• Fast

• Simple

• Safe

• Efficient

During the sample preparation step, you can have samples of varied size. If the initial size

of the sample is very big – over 10 mm -, it is necessary to undertake a pre-crushing process,

named primary reduction. After this first reduction you can proceed to use other equipment such as

a vibratory disc mill or a ball mixer mill, which shall help to reach the requested final analytical

granulometry.

The Equilab Jaw Crushers have been especially designed for a quick and efficient

primary size reduction of semi-hard, hard, brittle and tough materials.

Working process. The manual adjustment system with analogue control lets the user select

the final desired diameter for the sample through an analogue signal in a control screen located

on the left-hand side of the unit. The sample is fed via a “anti-rebound” hopper and falls directly

to the crushing chamber. Here a strong grinding process starts, due to the powerful action of a

movable jaw against a fixed one, the sample being crushed between both. When the sample

reaches an equal or inferior size than the one selected, it fells in a removable container.

Safe. With the “anti-rebound” hopper, it is possible to safely feed the unit even when

operative. All the moving parts of the unit are protected to ensure the safety of the user.

The Crusher has got electrical overload protection.

Fast. The power of the engine reaches the moving jaw via an eccentric shaft, causing an

elliptical movement in the part, extending thus the crushing and friction area.

Method. The breaking of the sample takes place in the inside of the crushing chamber under

the high pressure level exerted between the movable and the fixed jaw, and the interaction

with the other pieces of the sample

.

.

Leave A Comment