FX Electric Fluxers – Fuse Bead Machine

The FX Electric Fluxers – Fuse Bead Machine is a high-performance laboratory solution designed for precise and repeatable fuse bead sample preparation. Built for modern analytical laboratories, it ensures consistent fusion results essential for XRF and elemental analysis.

High-Precision Fuse Bead Preparation

FX Electric Fluxers use controlled electric heating to deliver uniform temperature distribution, reducing sample loss and operator error. This makes them ideal for laboratories handling minerals, cement, ores, glass, and geological samples.

Key Features of FX Electric Fluxers

Accurate and repeatable fusion bead results

Electric heating for stable temperature control

Ideal for XRF sample preparation

User-friendly operation and enhanced safety

Suitable for high-throughput laboratory environments

Applications

FX Electric Fluxers are widely used in:

Mining and mineral laboratories

Cement and construction material testing

Geological and environmental analysis

Research and quality control laboratories

Why Choose FX Electric Fluxers?

Compared to manual fusion methods, FX Electric Fluxers – Fuse Bead Machine improves analytical accuracy, reduces preparation time, and ensures compliance with laboratory standards. Its reliable performance makes it a preferred choice for professionals demanding precision and efficiency.

The new generation in fusion units is modular.

You can start by purchasing a single station unit (FX1) and then have the

possibility of extending the capacities of the fluxer at any time by acquiring a new

unit and connecting it to the initial one.

That way one working station (FX1) can become a two station unit (FX2) or a three

station unit (FX3).

If to this feature we add the fact that the FX Fluxers are high productivity units, we

have an unrivalled equipment.

.

.

The FX fluxers represent a great step forward from the well know F1 and F2 models, and have been especially

designed to prepare glass disks (beads) for analysis by XRF, and dissolutions for AA/ICP. They produce,

quickly and accurately, beads (with Lithium Borates) and acid dissolutions.

Efficient both in high and low temperatures, you can customize your fluxer to up to three modules controlled

by a single PC, keeping however the capacity of each module to work independently.

Features

The FX Series units are a step ahead from other units of their generation as they heat by electric induction in

an homogeneous, quick and efficient way.

These are highly automated units able to control and monitor in real time each step of the fusion process

from one (FX1) to three (FX3) samples, maintaining the operative Independence of each module.

The FX Series include an optical pyrometer oriented to the base of the crucible and with which you can check

the fusion temperature at all times.

A powerful interactive software gathers and displays all the information. The result is a unit able to thoroughly

control and modify the fusion process of each sample in real time.

Together with its innovative heating system by induction you may find a constant temperature check up system,

and a great software. The result is a unit that can control and modify comprehensively and at all times

the fusion process of each of the samples, in real time.

Operation

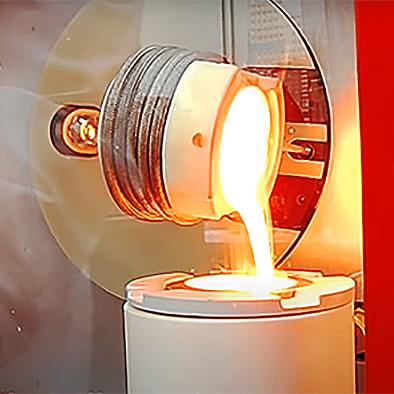

In the FX Series units the heating is achieved by a high frequency electromagnetic field generated in the

inside of a coil – no flame nor direct contact -, efficiently heating up the crucible in a short time.

Quicker

The heating by induction is noticeably quicker, more accurate, cleaner, and more dependable than any

other system.

It allows you to reach very high temperatures (1200ºC) in seconds and to control them easily. Any changes

are so swiftly applied that it makes it possible to have a detailed control of the fusion in real time. The only

parts of the unit that actually heat up are the ceramic holders – this allowing to reduce the times between

fusion cycles, as it is not necessary to cool down large heated up surfaces -.

Flexibility

Each of the modules can work synchronized with the others or independently, with different programs each,

for example to prepare samples of varied nature.

This freedom enables the user to to prepare new samples and process them the moment each working

module finishes the current execution, making a continuous cycle that increases production noticeably.

Better features

• The programmable crucible stirring mechanism allows you to obtain a higher homogenization of the samples

during the heating process.

• An optical pyrometer pointing to the base of the crucible carries out a constant check up of the fusion

temperature.

• A programmable cooling system for crucibles and molds speeds up the cooling of crucible and mold

most effectively.

• An exclusive gas extraction system allows for the unit to be installed without exhaust hoods.

As safety measure, the door is blocked during the time when the temperature inside may represent a

risk for the user.

• The coil is cooled down via a closed water circuit with a small cooling system – no water consumption

or refrigerant fluids -.

Low consumption

The induction system speeds up the heating process with a very moderate electrical consumption.

Maximum consumption 9000W, tested with the simultaneous heat-ing up of three crucibles and three molds

Leave A Comment